Materialities of Theobroma cacao L.

Biomaterial Experimentations from the Field of Design

18/02/25

Paula Cermeño

6 min

In the Mundo en Desnivel gastronomic experience at Central, one of the courses is called Cacao Chuncho. This course highlights the specific characteristics of the Chuncho variety of Theobroma cacao L., cultivated in the province of La Convención, in the jungle of the Cusco region. When we hear “cacao,” we often think of “chocolate,” but the Cacao Chuncho course reveals the full range of flavors and textures that different parts of the fruit can offer. In reality, chocolate production only uses the inner part of cacao seeds, which represents about 9% of the fruit’s total weight. The cacao production cycle generates many other usable byproducts, both during harvest and roasting, that are often overlooked.

As part of Mater’s Theobromas Project—which investigates different species of Theobroma, such as cacao, macambo, and cupuaçu—I was tasked with exploring Theobroma cacao L. from a material perspective. In today’s landscape of industrial and product design, designers are increasingly interested in developing utilitarian objects that prioritize responsible material sourcing and manufacturing processes, beyond just user functionality and comfort. Mater’s methodology, which stems from researching species, processes, and local contexts to formulate applications and approaches aligned with the territory, presents a unique opportunity. The materiality of objects can emerge from the same diversity and productive cycles that shape food.

Cacao Harvest in La Convención, Cusco. The pod is split open to extract the cacao seeds, still covered in mucilage. Photograph by Camila Novoa.

The Biomaterials with Theobroma cacao L. Project was developed by an industrial design team composed of Maria Paula Loveday and myself, in constant dialogue with the Mater team. Through conversations with Ariadna Oliveri, Mater’s gastronomic scientist, and Nilver Melgarejo, a specialist from the Theobromas Project, we learned that during the cacao harvesting stage, significant volumes of cacao pods remain in the fields and are discarded since the primary ingredient for chocolate-making is the inner seeds. These discarded pods can be harmful to the environment and soil, as they create ideal ecosystems for the proliferation of pathogenic microorganisms and mosquitoes. At certain times of the year, cacao tree leaves are another material found in the fields. After fermentation and roasting, the cacao husks are also separated. Although they can be used to make infusions, post-infusion husks are typically discarded as well.

Considering these byproducts as potential resources, the main objectives of the project were:

To develop material samples to understand the specific properties of each cacao-derived input (husk, pod, leaf).

Based on these properties, to propose applications for future objects, both within the context of the experiences at Central, Kjolle, and MIL, as well as in other scenarios within the value chain.

The Biomaterial Diversity of Cacao

Throughout this exploration, a recurring question emerged: What defines whether a material is a biomaterial? If we aim for circular design, a biomaterial is composed entirely of ingredients that, at the end of an object’s life cycle, can decompose without harming the environment, being biodegradable or even compostable. Unlike recycled plastics or composite materials containing synthetic ingredients, a biomaterial can return to the earth. With this in mind, all the ingredients used in the project were selected to ensure the subsequent biodegradability of the material samples and any potential objects derived from them.

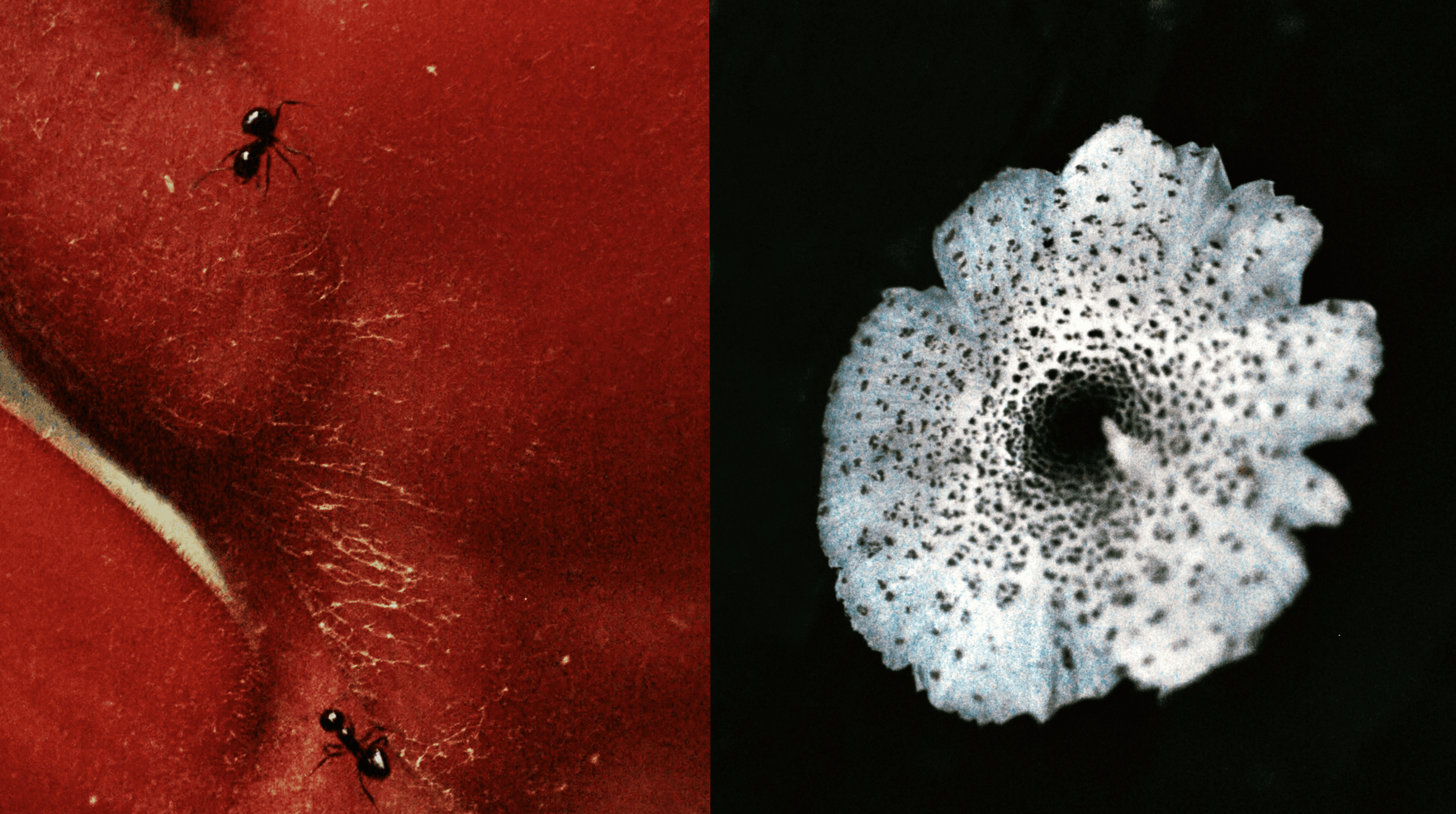

Cacao Husk in Algae-Derived Biofilm, Prior to Drying.

The preparation of biomaterials involved formulating recipes and making trial-and-error adjustments. In a setup similar to a kitchen, we combined cacao byproducts with various binders, using water as a solvent and, in some cases, additive ingredients to modify color and texture. Given the available quantities of each material, we produced most of the samples with cacao husks, followed by the pod, and used cacao leaves for a couple of specific tests. The variety of materials developed reflects both the distinct properties of the cacao inputs and the management of proportions and drying times.

Another important variable in our material exploration was the location where the project was developed: the Barranco district of Lima, where Casa Túpac and Mater’s offices are located. This coastal setting, with its high humidity levels, made exposing the samples to the open air a test in itself, helping us validate processes and refine material formats. The results varied in tone, hardness, flexibility, water resistance, and more—sometimes changing from one week to another. Beyond practical considerations, designing materials and objects for specific geographic contexts holds intrinsic value, where an object’s materiality is closely linked to place.

Samples Made from Cacao Pod and Husk with Various Binders.

As we guided the project toward practical applications, the samples gradually formed a palette of colors and textures. We began to notice differences between those made with cacao pods and those made with husks. The cacao pod provided a uniform, granular texture similar to chamotte ceramics, with warmer, lighter brown tones. Meanwhile, samples made with husks maintained a deep brown, almost reddish hue. The varying fragment sizes in the husk material created patterns and contrasts similar to those seen in terrazzo flooring. If the husk fragments remained as intact as possible, the material highlighted the natural shapes and sizes of the cacao seeds.

Another key factor in the exploration was scent, adding to the multi-sensory qualities of cacao biomaterials. Since the husk envelops the seeds, it retains a strong chocolate aroma. This became especially noticeable during the drying process of husk-based pieces, when the entire Mater office was filled with the scent of chocolate. Even eight months later, the first samples stored in sealed containers still retained this characteristic. In contrast, materials made from cacao pods initially had a fruitier, though less intense, aroma. If at any point we had trouble distinguishing samples by color, their scent helped identify their original input. Over time, the continuous experimentation and accumulation of samples have helped create a material library that reflects the unique properties of cacao byproducts.

Conceptualization and Applications

Since biomaterials are, by definition, biodegradable, their life cycle plays a crucial role in designing new objects. It is essential to formulate materials with lifespans appropriate for their intended applications and, likewise, to imagine applications that align with the properties of these new materials.

Initially, the exploration focused on two main material formats:

Solids: Samples that originated as pastes and, through drying, hardened into non-flexible volumes, sheets, or filaments.

Thin, flexible sheets: Laminates that retained a certain degree of flexibility.

Flexible Sheet Made from Crushed Cacao Leaves.

The direction of potential applications was guided by discussions with Virgilio and Malena Martínez. From the perspective of Central’s gastronomic experience, there was interest in developing tableware for serving cacao-related courses, such as Cacao Chuncho. After reviewing the initial tests, Virgilio requested that we explore the development of trays made from husks, as well as three-dimensional structures to present cacao bars. For these new iterations, we considered the restaurant’s requirements: ease of cleaning, resistance to water exposure, and the ability to support weight.

Tray Made from Whole Cacao Husk and Bowl Made from Ground Husk.

Bowl Made from Ground Cacao Husk, Constructed via Extrusion.

In the case of the cacao husk tray, we created increasingly larger sheets to progressively validate our formulations. We molded the biomaterials in their wet state, and as they dried, the initial shapes of the objects changed. While distortions or cracks in the dried objects could be seen as flaws, we considered these transformations as potential characteristics for a production process in which each piece would be slightly different.

For the construction of three-dimensional structures, we opted to create pastes using ground cacao husk or pod, aiming to generate filaments or threads with the help of an extrusion syringe. Depositing the material through a syringe allowed us to control the filament’s placement to create two-dimensional designs or, with the use of molds and matrices, to form lightweight volumes.

Cacao Husk Samples Created Using Filament Deposition (Extrusion).

The development of samples led us to envision different use scenarios for cacao biomaterials, both in the short term with small production runs and in the long term, considering extended development times and scalability. Given the volume of cacao byproducts, it was also important for Mater to map applications beyond the restaurant context. Alongside the objects designed for Central’s experience, we worked with Malena to validate and explore applications that could have an impact in other fields.

Future Steps

This initial stage of the Biomaterials with Theobroma cacao L. project has helped define the potential for developing new materialities derived from food-related value chains. The project’s outcomes include an initial set of samples and prototypes that validate concepts for new objects, to be explored in greater depth.

Eight months after producing the samples, we have conducted a first selection based on their performance both in storage and in open conditions. These observations have helped solidify the viability of cacao biomaterials and guide the production of larger pieces. One example of this progress is the series of bowls we later designed for Hilos de Tiempo, Mater’s exhibition at the Museo Pedro de Osma, just a few blocks from Casa Túpac.

The project has also served as a foundation for the creation of Mater’s Department of Ideas and Application in Materials (I+A Materiales), which seeks to bridge gastronomy and industrial design for the development of new objects and materialities, in close dialogue with the territory.

Cacao husk as raw material (left) and as an object (right).

Team

Design, development, and execution:

Paula Cermeño, Product Designer, Director of I+A Materiales Mater

Maria Paula Loveday, Assistant in Industrial Design

Dialogue and advisory from Mater:

Ariadna Oliveri, Gastronomic Scientist

Nilver Melgarejo, Theobromas Project Specialist

Patricia Yraja, Project Director

Mater Leadership:

Malena Martínez

Virgilio Martínez